Knowledge Base

PET Bottle Blow Moulding & Plastic Bottle Making Machines

Shaping the Future of PET Packaging

In today’s fast-paced packaging industry, efficiency, durability, and cost-effectiveness are critical. At Dunamis, we specialize in advanced PET bottle blow moulding machines and plastic bottle making machines designed to meet the evolving demands of water, beverage, and consumer goods industries. Whether you are a startup bottling unit or a large-scale manufacturer, our range of bottle making machines ensures high productivity, low rejection rates, and consistent quality.

With years of expertise and a commitment to innovation, Dunamis has become a trusted name in the field of PET packaging technology. Our machines are engineered to deliver maximum output while minimizing energy consumption, helping businesses achieve sustainable growth without compromising performance. By combining cutting-edge automation, precision engineering, and robust design, we provide complete solutions that not only meet today’s industry standards but also prepare our clients for the future of packaging.

What Is a Blow Moulding Machine?

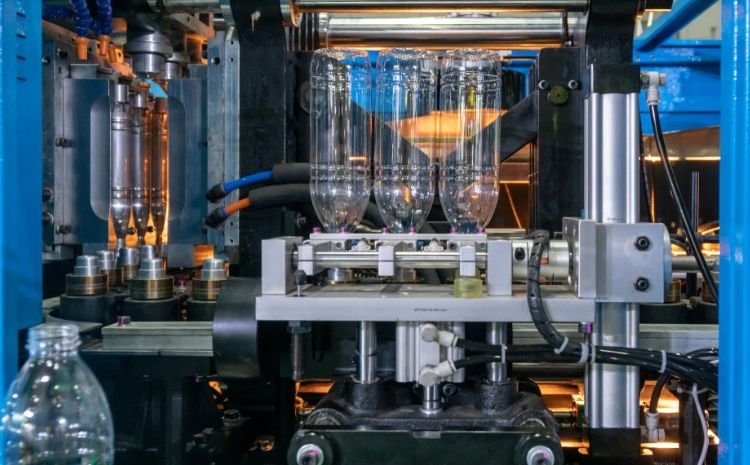

A blow moulding machine is the backbone of PET bottle production. It uses heat, air pressure, and precision moulds to transform preforms into strong, durable, and perfectly shaped bottles. From a simple plastic bottle making machine to a fully automatic blowing machine, Dunamis provides technology tailored to your requirements.

Our PET blowing machines are engineered with state-of-the-art controls, ensuring uniformity in shape and size while reducing energy consumption.

In addition to speed and precision, modern bottle making machines also prioritize versatility. Dunamis designs machines that can adapt to different bottle shapes, sizes, and applications, whether for beverages, pharmaceuticals, cosmetics, or food products. This flexibility allows manufacturers to cater to diverse markets with a single system, giving them the competitive advantage of efficiency, reliability, and adaptability in an ever-changing packaging landscape.

Types of PET Blow Moulding Machines We Offer

At Dunamis, we provide a complete range of PET blow moulding machines designed to suit businesses of every size and production requirement. Each machine we manufacture is a blend of advanced technology, precision engineering, and long-lasting durability, ensuring that our clients receive the most reliable solutions for their packaging operations. From small-scale startups to high-capacity manufacturing plants, we deliver machines that are both cost-effective and capable of meeting the demanding expectations of today’s global market.

Our semi-automatic blow moulding machines are the ideal choice for small to medium-scale industries that want to combine flexibility with affordability. These machines are user-friendly and require minimal training, allowing operators to quickly adapt and achieve efficient output. They are particularly suited for businesses that are just entering the bottling industry or companies that operate with moderate production volumes but still want consistent, high-quality results. By offering strong performance at an affordable cost, semi-automatic solutions help businesses grow steadily while keeping investment levels manageable.

For larger manufacturers with higher production demands, our fully automatic PET bottle making machines deliver unmatched performance. These machines are engineered with state-of-the-art automation and precision technology, capable of producing thousands of bottles per hour with minimal human intervention. They ensure accuracy in shape, size, and thickness, maintaining strict quality standards across every single bottle. Fully automatic systems not only increase speed but also reduce manpower requirements, making them the perfect solution for companies that value productivity and cost savings on labor while maintaining superior product consistency.

To further maximize operational efficiency, Dunamis also offers online PET blowing systems, which are seamlessly integrated with filling lines. Unlike standalone machines, these systems allow preforms to be blown directly into bottles and then filled immediately, eliminating unnecessary handling and reducing downtime. This streamlined process helps companies save time, minimize errors, and achieve a smooth, continuous production flow. For high-output industries such as water bottling plants and carbonated drink manufacturers, this level of integration is a game-changer that ensures consistent supply and efficiency.

We also specialize in jar blow moulding machines, specifically designed for producing large-capacity PET jars. These machines are particularly useful for industries that package edible oils, water, pickles, dry fruits, and other bulk liquid or solid products. Durability and strength are key in jar production, and our technology ensures that the end product can withstand transportation, stacking, and long shelf life while maintaining its integrity. By addressing the unique requirements of jar packaging, we provide solutions that extend beyond standard bottles and open new opportunities for businesses in diverse markets.

At Dunamis, we understand that every client has unique needs, which is why we provide tailored blow moulding solutions that match your manufacturing goals. Whether you require a bottle making machine for beverages, pharmaceuticals, cosmetics, or specialty applications, our machines are designed to deliver outstanding performance while keeping production costs under control. By combining automation, flexibility, and durability, Dunamis ensures that businesses are well-equipped not only to meet today’s packaging demands but also to scale for future growth.

Advantages of PET Blow Moulding Machines

One of the biggest advantages of our PET blow moulding machines is their high production speed. Designed for efficiency, these machines are capable of producing thousands of bottles per hour, making them an excellent choice for businesses that require large-scale output without compromising on quality.

Our machines are also highly cost-effective, thanks to their low maintenance requirements and advanced energy-saving features. By reducing power consumption and operational costs, they allow manufacturers to achieve greater profitability while maintaining sustainable production practices.

Another key benefit is flexibility. Our blow moulding machines can be easily adapted to produce different bottle sizes and shapes, catering to the diverse needs of industries such as beverages, pharmaceuticals, cosmetics, and packaged foods. This versatility ensures that businesses can meet changing market demands quickly and efficiently.

Durability is at the core of every machine we manufacture. Built with premium-grade components, our PET blow moulding machines are designed for long-lasting performance, ensuring reliability and consistent output even under continuous, high-pressure production conditions.

Finally, our solutions are enhanced with automatic functionality. From preform heating to moulding and cooling, every stage of production is streamlined with advanced automation. This not only saves time and labor costs but also guarantees precision and uniformity across every bottle produced.

Applications across Industries

Our advanced PET blowing machines and plastic bottle making machines are designed to serve a wide range of industries with efficiency and reliability. In the beverage industry, they are widely used to produce bottles for packaged drinking water, carbonated soft drinks, and fruit juices, ensuring durability and consistent quality. The pharmaceutical sector also benefits from our technology, as it enables the production of medicine bottles and specialized healthcare packaging that meet strict safety standards.

In addition, the cosmetics industry relies on our machines to create attractive and durable packaging for shampoos, lotions, and other personal care products, helping brands stand out on the shelves. The food industry is another key area where our solutions are applied, with PET bottles and jars manufactured for edible oils, vinegar, sauces, and other consumables. By offering versatile solutions that adapt to different packaging needs, our machines support businesses across multiple sectors in achieving both functionality and brand appeal.

Our bottle making machines also play a vital role in the household and cleaning products industry, where sturdy PET bottles are required for detergents, disinfectants, and cleaning solutions. These products demand packaging that is both durable and safe for handling, and our technology ensures containers can withstand storage, transport, and frequent use without compromising on quality. This makes Dunamis a trusted partner for brands looking to maintain strong consumer trust through reliable packaging.

Furthermore, the agro-chemical and industrial sectors benefit significantly from our automatic blowing machines, which produce high-strength containers suitable for fertilizers, pesticides, lubricants, and other chemical products. These industries require packaging that offers maximum protection and long shelf life, and our machines deliver exactly that. By catering to both consumer-driven and industrial-grade packaging needs, Dunamis ensures that businesses across the globe have access to world-class PET packaging solutions tailored to their specific requirements.

Why Dunamis is the Right Choice for Filling Solutions

Dunamis stands out as a trusted partner for businesses looking to scale their production with reliable technology. We offer a wide range of plastic bottle filling machines that cater to diverse requirements, from small-scale operations to large-scale industrial plants. Our expertise is proven through global installations across water plants and soda factories, showcasing our ability to deliver solutions that perform consistently in real-world conditions.

Beyond the machines themselves, we pride ourselves on providing 24/7 customer service and technical support, ensuring our clients experience uninterrupted operations and timely assistance whenever needed. With a proven track record in delivering efficiency and reliability, Dunamis has become a go-to name in the bottling industry. When you choose our advanced water bottling machines, you are not just investing in equipment—you are investing in long-term success and sustainable growth for your business.

PET Bottle Manufacturing Process Step-by-Step

The future of PET blow moulding machines is evolving rapidly, driven by the global demand for smarter, faster, and more sustainable manufacturing solutions. As industries shift toward automation, the next generation of PET bottle making machines will be equipped with advanced control systems, IoT-enabled monitoring, and AI-driven quality checks that ensure consistent performance with minimal human intervention. Energy efficiency is another key focus, with modern machines designed to consume less power, optimize heating cycles, and reduce overall operational costs without compromising output.

At the same time, the emphasis on eco-friendly production continues to grow, with innovations in lightweight bottle designs, recyclable materials, and reduced plastic waste playing a crucial role in shaping the packaging industry. At Dunamis, we are committed to staying ahead of these trends by developing automatic blowing machines that combine intelligent technology with sustainable engineering. Our goal is to help manufacturers meet rising market demands while reducing their environmental impact, ensuring that the future of packaging is not only efficient but also responsible and eco-conscious.

Looking ahead, smart integration will redefine the way blow moulding operations function. Machines of the future will not only deliver high-speed performance but will also provide real-time data analytics for predictive maintenance, minimizing downtime and enhancing productivity. With the rise of Industry 4.0, connectivity between PET blowing machines and other packaging systems will create fully automated production lines that are flexible, scalable, and capable of adapting instantly to changing market demands. By embracing these advancements, Dunamis is setting new benchmarks in the industry, ensuring our clients are always equipped with cutting-edge solutions that secure long-term competitiveness and growth.

Challenges in PET Bottle Production

While PET blow moulding machines have revolutionized packaging, manufacturers still face several challenges in daily operations. Maintaining consistent bottle quality is one of the biggest hurdles, as even minor deviations in temperature or air pressure can lead to defects. Businesses also encounter rising energy costs, making it essential to use machines that optimize power consumption without sacrificing speed. Another challenge is the growing demand for customized bottle designs. Traditional systems often struggle to switch between different bottle shapes quickly, causing production delays. Dunamis addresses these pain points with machines that are engineered for reliability, flexibility, and energy savings, ensuring uninterrupted operations even in high-pressure environments.

Beyond technical issues, global competition pushes companies to constantly upgrade their systems. Small and mid-scale manufacturers may find it difficult to keep up with demand spikes, especially when competing against larger enterprises with fully automated plants. Dunamis provides solutions tailored for every scale of operation, making advanced bottle making machines accessible for both small startups and large corporations. By resolving these industry challenges, our technology enables manufacturers to focus on growth rather than technical setbacks.

How Dunamis Technology Improves Efficiency

Efficiency in PET bottle manufacturing goes beyond speed—it involves optimizing every stage of production. Dunamis machines are designed with infrared heating systems that ensure preforms are heated evenly, reducing material wastage and improving bottle strength. Our automatic blowing machines also use intelligent sensors that monitor air pressure and mould alignment, minimizing human error and ensuring uniformity across batches. These innovations result in lower rejection rates, saving both time and raw material.

Another efficiency factor is ease of operation. Many traditional machines require skilled technicians for constant supervision, but Dunamis integrates PLC-based control panels and user-friendly interfaces, allowing operators to manage production with minimal training. This reduces dependency on labor while maintaining consistent quality output. By focusing on both automation and operator convenience, our technology ensures maximum productivity with minimal downtime.

Cost-Effectiveness and ROI Benefits

For manufacturers, investing in new equipment always comes with questions about return on investment. Dunamis machines are designed not only for performance but also for long-term savings. With their energy-efficient preform heating technology, businesses can cut down electricity costs significantly. The durability of our PET bottle making machines means fewer breakdowns and reduced maintenance expenses, extending the machine’s life cycle and increasing ROI.

Additionally, Dunamis machines support fast mould changeovers, allowing manufacturers to quickly switch between different bottle sizes and product lines. This flexibility minimizes idle time and helps businesses respond faster to shifting market demands. When factoring in reduced waste, higher production speeds, and lower energy consumption, the overall cost-effectiveness of Dunamis machines becomes clear. Companies that adopt our technology see measurable savings within the first few production cycles, making it a wise long-term investment.

Sustainability and Eco-Friendly Practices

In today’s packaging industry, sustainability is not just a trend—it’s a necessity. Consumers and governments worldwide are demanding eco-friendly packaging solutions, and PET bottles remain one of the most recyclable packaging materials available. At Dunamis, we align with these values by engineering plastic bottle making machines that support lightweight bottle production without compromising durability. Producing lighter bottles reduces raw material usage, lowers transportation costs, and minimizes the environmental footprint.

Our machines are also optimized for energy conservation, using advanced heating and cooling technologies that reduce power consumption. Additionally, Dunamis encourages the use of recyclable PET materials, helping brands adopt circular economy practices. By enabling eco-friendly production, we ensure that our clients are not only meeting consumer expectations but also complying with stricter environmental regulations across global markets.

Global Reach and Industry Recognition

Dunamis has established itself as a trusted name not only in India but also across international markets. Our PET blowing machines and automatic bottle making machines are installed in multiple countries, serving industries ranging from bottled water and soft drinks to pharmaceuticals and cosmetics. This global footprint demonstrates our ability to adapt to diverse regulatory standards and market requirements.

What sets us apart is not only our machinery but also our after-sales support. With a dedicated team of engineers available 24/7, we provide installation assistance, operator training, and maintenance services that ensure smooth operations. Many of our clients have grown from small regional bottlers to large-scale exporters with the help of our technology. This proven track record highlights why Dunamis is a preferred partner in the PET packaging sector.

Innovation and R&D at Dunamis

Continuous innovation is the foundation of Dunamis. Our in-house research and development team constantly works on integrating new technologies into our machines. Recent innovations include faster heating systems that reduce energy usage by up to 30%, modular machine designs that make maintenance easier, and IoT-enabled performance tracking that helps manufacturers analyze production data in real-time. These R&D efforts not only improve machine performance but also ensure that our clients are always ahead of industry trends.

We also collaborate with packaging experts and consumer brands to design machines that cater to unique requirements, such as specialized bottle designs for premium beverages or high-strength jars for edible oils. This customer-focused approach allows Dunamis to deliver customized bottle making machines that balance speed, precision, and creativity. By investing in R&D, we ensure our machines evolve alongside industry demands, positioning our clients for long-term success.

Future of PET Blow Moulding

The future of PET blow moulding machines is being shaped by automation and smart manufacturing technologies that bring greater efficiency and reliability to the packaging industry. Modern PET bottle making machines are no longer limited to high-speed production alone—they are now equipped with intelligent control systems, IoT-enabled connectivity, and AI-based monitoring that ensure accuracy and consistency in every cycle. With these advancements, manufacturers can reduce downtime, predict maintenance needs, and achieve seamless integration across production lines, resulting in smoother operations and higher productivity.

Another key focus for the coming years is energy efficiency. Rising production costs and growing environmental concerns are driving manufacturers to adopt solutions that consume less power while maximizing output. At Dunamis, our automatic blowing machines are designed with advanced heating systems and optimized airflow technology to minimize energy usage during preform heating and bottle moulding. These energy-saving innovations not only help reduce operational expenses but also contribute to building a more sustainable and eco-conscious manufacturing ecosystem, which is becoming a critical factor for global competitiveness.

Sustainability and eco-friendly production are also at the forefront of packaging evolution. The demand for lightweight bottles, recyclable materials, and reduced plastic waste is shaping the future of PET bottle making machines. Dunamis is continuously innovating with smart designs that support the use of thinner preforms, sustainable raw materials, and processes that minimize environmental impact. By combining automation, energy savings, and eco-conscious engineering, we are ensuring that our clients are equipped not only to meet today’s production demands but also to stay ahead of tomorrow’s regulatory and consumer expectations.