Knowledge Base

Automatic & Fully Automatic BOPP Labeling Machines: The Future of Efficient Bottle Labeling

Labeling is one of the most important aspects of packaging. In high-speed production lines, like mineral water bottling or beverage or FMCG units, precision, consistency, and speed are critical. The right equipment can make the difference between higher quality products, less downtime and wasted inputs, and a well-marketed product that attracts buyers to your brand.

Dunamis machines stocks a range of automatic and fully automatic BOPP labeling machines, which are designed specifically for modern bottling plants and units. Efficient, precise, and reliable over the long term, the systems from Dunamis are the go-to option for mineral water manufacturers, food and beverage units, and FMCG units in India.

Dunamis machines labeling machines are BOPP labeling machines that provide a professional, seamless appearance thanks to the use of Biaxially Oriented Polypropylene or BOPP film labels that are moisture and wear-resistant.

From mineral water bottle labeling machines to water bottle labeling machines and a range of automatic BOPP labeling machines, Dunamis machines has the right system to improve every element of your production line.

What is A BOPP Labeling Machine?

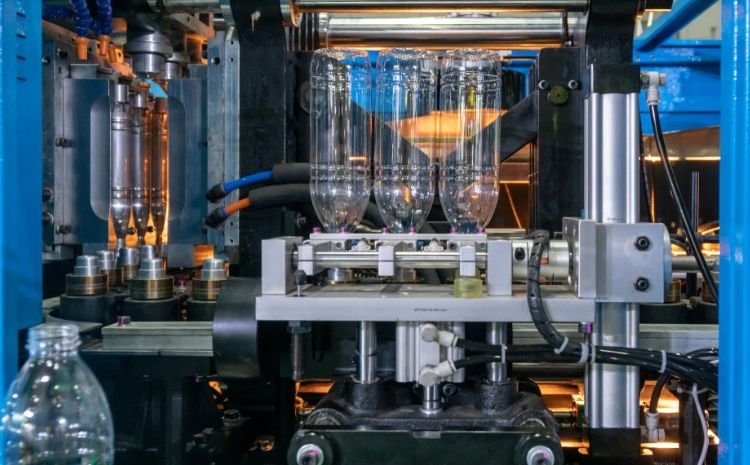

A BOPP labeling machine is an automatic labeling machine that applies film labels to bottles and containers. BOPP is short for Biaxially Oriented Polypropylene, and BOPP labels have become very common in the water and beverage industries. This is largely because the labels are moisture-resistant with high gloss and print quality.

The BOPP labeling machine has a system in it that automatically unrolls a roll of printed BOPP film, cuts it to the size of the label, adds a layer of hot-melt glue, and then wraps the label around the bottle. The bottle is fed into the machine, and the label that has been attached to the bottle is set permanently.

BOPP Labels can stay in good visual condition over paper labels when stored in refrigeration or moisture. BOPP labels are also tear-resistant, scratch-resistant, and fade-resistant, so they last longer and can provide you with a more professional finished look.

Benefits of BOPP Labeling Machines for Water Bottles

BOPP film labels have become very common in the water bottling industry and the beverage industry overall. The primary reason for this is that BOPP labels can withstand moisture, while paper or PVC labels become disfigured or even peel off. BOPP Labels Are:

Waterproof

The number one gripe when it comes to water and beverage bottle labelling is the inevitable loss of label quality when subject to cold or damp conditions. Labels printed on paper or PVC can easily wrinkle, curl, or worse, become detached in the presence of condensation or refrigeration during shipping or storage.

BOPP labels are 100% waterproof, and as the non-polar film is completely hydrophobic, droplets of water or vapor cannot penetrate the surface or dissolve the glue layer.

BOPP labelling machines are ideal for mineral water, soft drinks, and any other liquid products, as the labels will not be affected by cold storage or wet bottling line conditions. Labels on your products stay flat, smooth, and fully intact with no wrinkling or curling, so your brand image remains consistent from filling line to retail shelf.

Robust

Products will often go through a lot during their lifetime. Transportation, handling, and a need for long shelf life all demand durability. This is where BOPP labels excel, offering superior mechanical resistance.

The BOPP film is tougher against tearing, scuffing, and abrasion. The biaxial orientation process applied during the manufacturing of the film improves the tensile strength. As a result, the labels hold their shape and look sharp, even at high-speed labelling or when they come into contact with other surfaces in the packaging machinery.

The surface is also UV, chemical, and moisture resistant to prevent colour loss or print fading over time. The result is a product that always looks fresh and new, which is important from the moment the bottles arrive in the warehouse until the end user or consumer uses them.

Automatic and Fully Automatic BOPP Labeling Machines by Dunamis

The automatic and fully automatic BOPP labeling machines by Dunamis have been created to make the process of labeling easier, efficient, accurate, fast, reliable, and consistent. A mineral water bottle labeling machine or water bottle labeling machine from Dunamis, we have the right unit to improve the process of labeling.

Dunamis automatic and fully automatic BOPP labeling machines are made in various categories, such as:

- Automatic BOPP labeling machine

- Fully automatic BOPP labeling machine

- Mineral water bottle labeling machine

- Water bottle labeling machine

Below, we take a look at all the categories of automatic and fully automatic BOPP labeling machines by Dunamis.

1. Automatic BOPP Labeling Machine

Automatic BOPP labeling machine is a great option for those who are in need of a bottle labeling machine that is automated, is perfect for medium to large-scale production lines and bottling lines, and has automatic cutting, gluing, and labeling.

This Automatic BOPP labeling machine ensures that the uniformity of the labels is consistent and ensures that the labels are stuck to every bottle with uniformity and precision with its servo-driven mechanism that interlocks the bottle feed system, cutting unit, and glue dispensing unit.

Features:

- Speeds of up to 6,000 bottles per hour.

- Suitable for PET, HDPE, glass, and composite.

- Hot melt glue dispensing system with servo motor-based glue dose control.

- PLC and HMI-based operation.

- Modular design with simple installation and bottle changeover.

- Stainless steel frame and all food-grade components.

- Compact and space-saving design, suitable for integration into your existing line.

Best for those in the beverage industry who need to be able to balance the efficiency of an automated BOPP labeling machine with one that is relatively cost-effective.

2. Fully Automatic BOPP Labeling Machine

The fully automatic BOPP labeling machine, like the automatic BOPP labeling machine, is created to make sure that every process is completed automatically and flawlessly.

This is specifically made for a high-speed production line as it has a servo-driven label registration system with an interlocked unit to stop the machine. In case of no bottles, this safety feature is called “No bottle, no label”.

Highlights:

- Labeling speed up to 12,000 bottles per hour

- Servo-driven label registration system with an interlocked unit to stop the machine (in case of no bottle), named “No bottle, no label”.

- Temperature-controlled glue rollers.

- Synchronized bottle rotation with a high-speed bottle turret

- Error diagnostics and auto stoppage for machine safety

- Energy-efficient motors for lower operating costs.

Perfect for large water bottle manufacturing units that need their labeling machines to have the speed, performance, and efficiency, and that require them to be able to run on their own with minimal to zero supervision.

3. Mineral Water Bottle Labeling Machine

This mineral water bottle labeling machine is specifically designed for mineral water bottling lines and units and is made for bottles in wet or chilled conditions, where the bottle or liquid may get in the way of the label and its adhesion.

Made with all of the cutting-edge technology of the Dunamis automatic and fully automatic BOPP labeling machines, the Dunamis mineral water bottle labeling machine, specifically, is made for speed, hygiene, less human interaction, and more precision and accuracy with labels.

- 200 ml to 2-liter bottles

- PET and HDPE bottles.

- Adjustable label pitch for multiple label sizes.

- Hot-melt glue or cold-glue option available.

- Stainless steel enclosures for hygienic operation.

- Seamless integration with your filling machine and capping line.

The preferred choice for mineral water manufacturers who demand consistent speed, precision, hygiene, and labeling accuracy for every bottle all achieved without any manual intervention.

4. Water Bottle Labeling Machine

The water bottle labeling machine is a very versatile unit that can label bottles of different sizes, shapes, and types, including water bottles, juice bottles, or beverage bottles, for the bottled water industry, the juice industry, and the beverage industry.

This is a machine that has great features and ensures that the labeling of bottles with the uniformity of labels is consistent with a rapid production cycle.

- Adjustable speed depending on the flow of bottles.

- Round, square, or curved container, compatible with both.

- Automatic tension control system on the label roll.

- Servo-based feeding for the bottles for a more consistent wrap-around.

- Durable, low-maintenance, and with easy access to all the components.

Suitable for use either individually or with the help of automation for filling, capping, and shrink-wrapping

Overload Protection and Emergency Stop

Operator safety and machine integrity are not compromised in any way. Dunamis has overload sensors on the machine to monitor torque and pressure levels at critical points, such as the conveyor and labeling zone.

If abnormal load or any obstructions are detected, the machine will automatically stop to prevent further damage. Emergency stop buttons are strategically located on all sides of the machine to shut down the entire operation in case of any mishap or malfunction.

Clear and Transparent Guards for Easy Viewing

Dunamis BOPP labeling lines have protective clear polycarbonate guards around all moving parts, which operators can use to easily view the operation inside to check labels, glue, and bottle positioning without any exposure to the moving parts or mechanisms.

In addition, these guards also double up as an interlocking safety barrier, which stops the machine if it is opened while the machine is running.

Automatic Stop in Case of Absence of Bottle/Misfed

Precision optical sensors are placed to track each bottle going into and coming out of the labeling zone. If a bottle is missing, misaligned, or not properly set on the turret, the labeling machine immediately stops labeling to avoid any waste of glue or wrong label placement on the bottle or damage to machine parts. Dunamis offers a “no bottle–no label” feature, which ensures consistent labeling quality while also protecting the integrity of your product and equipment.

Maintenance and Service Support

Dunamis Machines is here to make sure that every installation of our machinery runs at its optimum level and is as efficient as it can be with the help of our after-sales service for maintenance, supply of spare parts, operator training, and on-site service for support.

Our service team is trained to deliver results that minimize downtime and also to increase machine life and make sure your investment keeps paying you dividends.

Fast Start-Up and Quick Shutdown

Dunamis’s BOPP labeling lines feature smart programming in PLC, which will enable you to start or stop the machine in seconds. Calibration of the temperature of the glue, heating up the glue, and label alignment during start-up will all be performed automatically without wasting the operator’s time or idle machine hours.

This will also help the machine not to run into long start-up routines or lengthy shutdown programs to wipe off any excess glue residue.

Reduction in Glue and Film Usage

In high-speed bottling lines, every drop of glue and every inch of film is a precious commodity. Dunamis labeling lines help you save on the cost of film and glue by applying the right amount and no more.

The feature of control in the glue roller, in addition to the servo-driven label-feed mechanism, precisely controls the glue amount applied during each bottle pass and does not result in overuse and smudging.

In addition to the above, optimized label-cutting also minimizes film wastage on the label applicator and helps in reducing both cost and waste. These attributes translate into lower operational costs and higher sustainability of your production process.

Balanced Bottle Flow for Jam-Free Operation

Machine conveyor, turret, and label applicator move in perfect harmony and synchronization, courtesy of the highly intelligent motion control system. Sensors on the turret track bottle spacing and alignment to the bottleneck of the labeling zone, and tweak the conveyor speed just right to avoid any backup in the labeling zone.

The result is glitch-free operation with each bottle handoff and uniform label placement even during maximum line speed, fewer stoppages, and improved overall production.

Self-Cleaning Glue Rollers

Maintenance of glue rollers is the bane of all labeling machines. Dunamis’ solution to the perennial problem of glue spillover, contamination, and cleaning the glue rollers is an automatic self-cleaning glue roller that wipes away all the excess glue and any possible build-up of glue.

This feature also ensures uniform glue distribution on all the bottles, contamination-free operation, and a long-lasting glue system. In addition, the self-cleaning mechanism can be automated to run during shutdown or manually done, to clean the glue roller at regular intervals or as and when required.

WHY CHOOSE DUNAMIS?

Trusted Engineering

At Dunamis, we take pride in engineering every machine to meet international manufacturing and safety standards. Quality and precision engineering go hand in hand, all the way through the build processes from frame construction through to servo motor alignments, every aspect is checked and double checked to make sure things line up and work the way they should.

We design our machines to be tough, rugged, and durable. Our machines are highly repeatable and easy to integrate with your production line, using 3D design and CNC fabrication with the highest quality raw materials. Our machines can take the punishment of long, continuous industrial operations.

This means you get a machine that will run smoothly with minimal breakages and more consistent accuracy over time, it will stay lined up and stable even when high-speed labeling.

Tailor-Made Machines

The layout of production lines is different in different plants; in the same way, no two Dunamis Machines are the same. Custom BOPP labeling machines made to your specifications can be integrated into the plant’s installation or fitted onto existing production lines.

All options are based on the bottle size, the label format, and your required line speed. From a manual bottling line up to a fully automatic setup, our engineers will collaborate with you to ensure the machine design allows you to run at peak efficiency, easy changeover between bottle sizes, and precise labeling.

Options range from automatic BOPP labeling machines for simple setups to fully automatic multi-station machines that ensure your investment matches both current needs and planned expansions.

Energy Efficient

Operational cost-savings are important when it comes to return on investment at Dunamis, we design machines with energy efficiency in mind. High torque energy-efficient servo motors, VFDs, and glue application systems are designed to ensure that your machine consumes no more resources than necessary to operate without affecting performance.

Precision-controlled hot-melt glue rollers are set to dispense just the right amount of glue required per label application without wastage and eliminate cleanup. The thermal management system is also intelligently designed to maintain consistent glue temperature to ensure the best glue adhesion and energy consumption.

Dunamis machines are engineered to use only the required energy and glue per bottle reducing running costs and environmental footprint, which is a great value-add for high volume producers looking to operate sustainably.

Scalable Solutions

All Dunamis machines are engineered with scalability in mind. The modular design allows customers to upgrade their production output, add additional labeling stations, or interface with new filling and packaging systems as business needs increase.

A one-station automatic BOPP labeling machine can be seamlessly scaled up to a dual-turret or dual-head machine with multi-stations at a later point without the need to change the entire machine.

Modularity means protecting your initial investment and giving you the flexibility to reconfigure your bottling lines as your production needs change over time whether this means increasing capacity, introducing new product lines, adapting to label format changes, or handling different speeds of operation with minimum disruption.

Hygiene Assurance

Smooth & rust/corrosion-free surfaces which do not permit glue/dust to stick and can be cleaned easily and quickly. The closed glue system will ensure that no contaminants can enter the glue nozzle or the glue rollers, keeping the labels clean and compliant without any dirt/particles on the labels.

Proven Performance

Dunamis machines are popular in key industries across India and internationally, trusted for long-term reliability, low maintenance, and consistent output quality.

Every machine is stress-tested under simulated running conditions before dispatch. Clients in the water bottling, FMCG, and pharma manufacturing sectors have reported 98% and above uptime and significant reduction in wastage, a testimony to the proven reliability of Dunamis