Fully Automatic Mineral Water RFC Machine

Flawless Hydration with the Fully Automatic Mineral Water RFC Machine

The fully automatic mineral water RFC machine is a state-of-the-art solution for efficient and hygienic bottled water production. Designed for high-speed operations, this fully automatic RFC machine integrates rinsing, filling, and capping into a single automated process. It ensures precision, consistency, and adherence to the highest standards of cleanliness and product safety. This mineral water filling machine is ideal for industries seeking to optimise productivity while maintaining strict hygiene protocols.

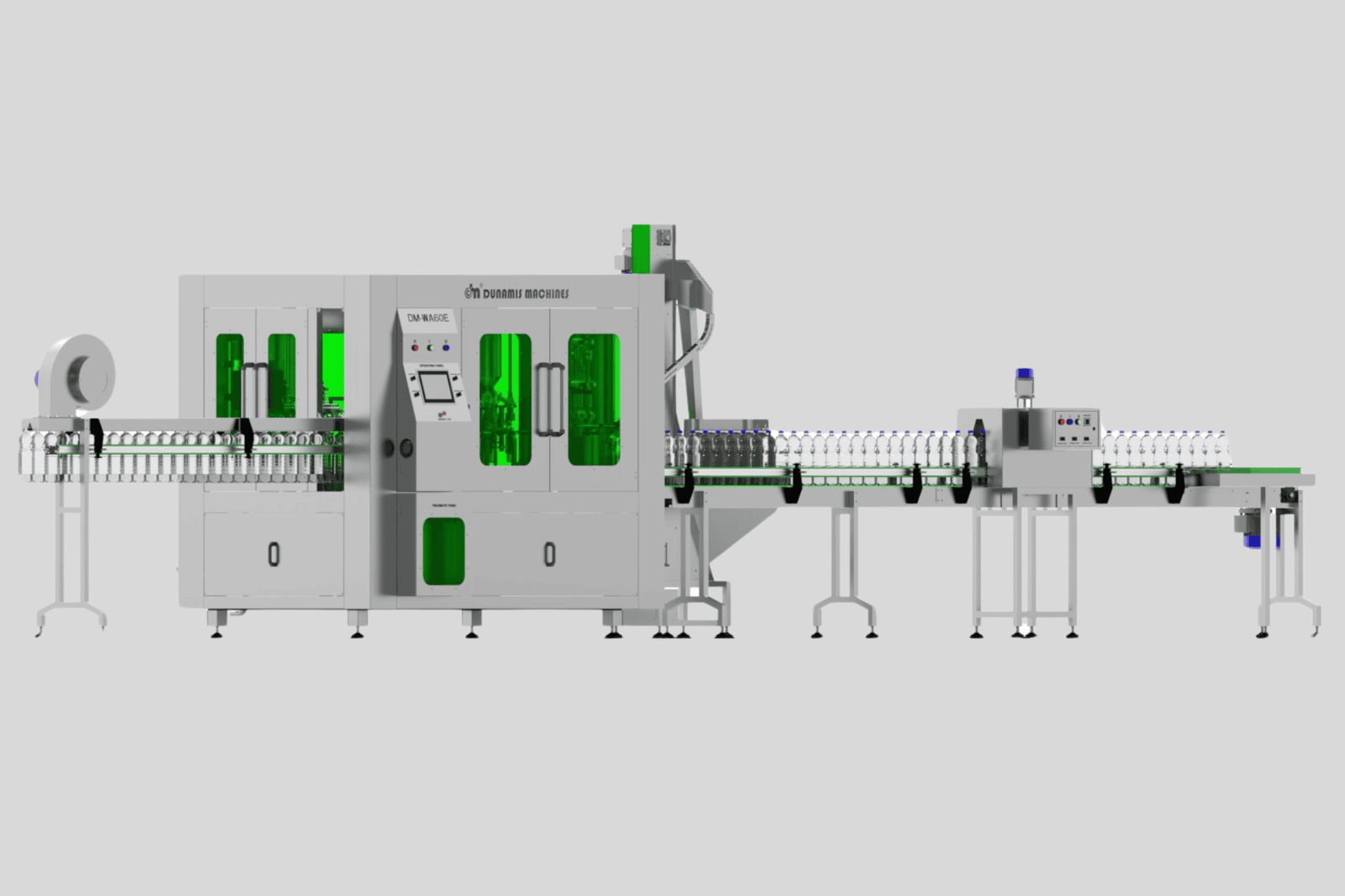

60 BPM Fully Automatic RFC Machine

The 60 BPM fully automatic mineral water filling machine is a high-performance solution tailored for bottling carbonated beverages with precision and efficiency. Operating at 60 bottles per minute, this machine seamlessly handles rinsing, filling, and capping processes, ensuring consistent quality and carbonation retention. Its user-friendly controls and hygienic design make it an ideal choice for businesses seeking reduced waste and enhanced productivity.

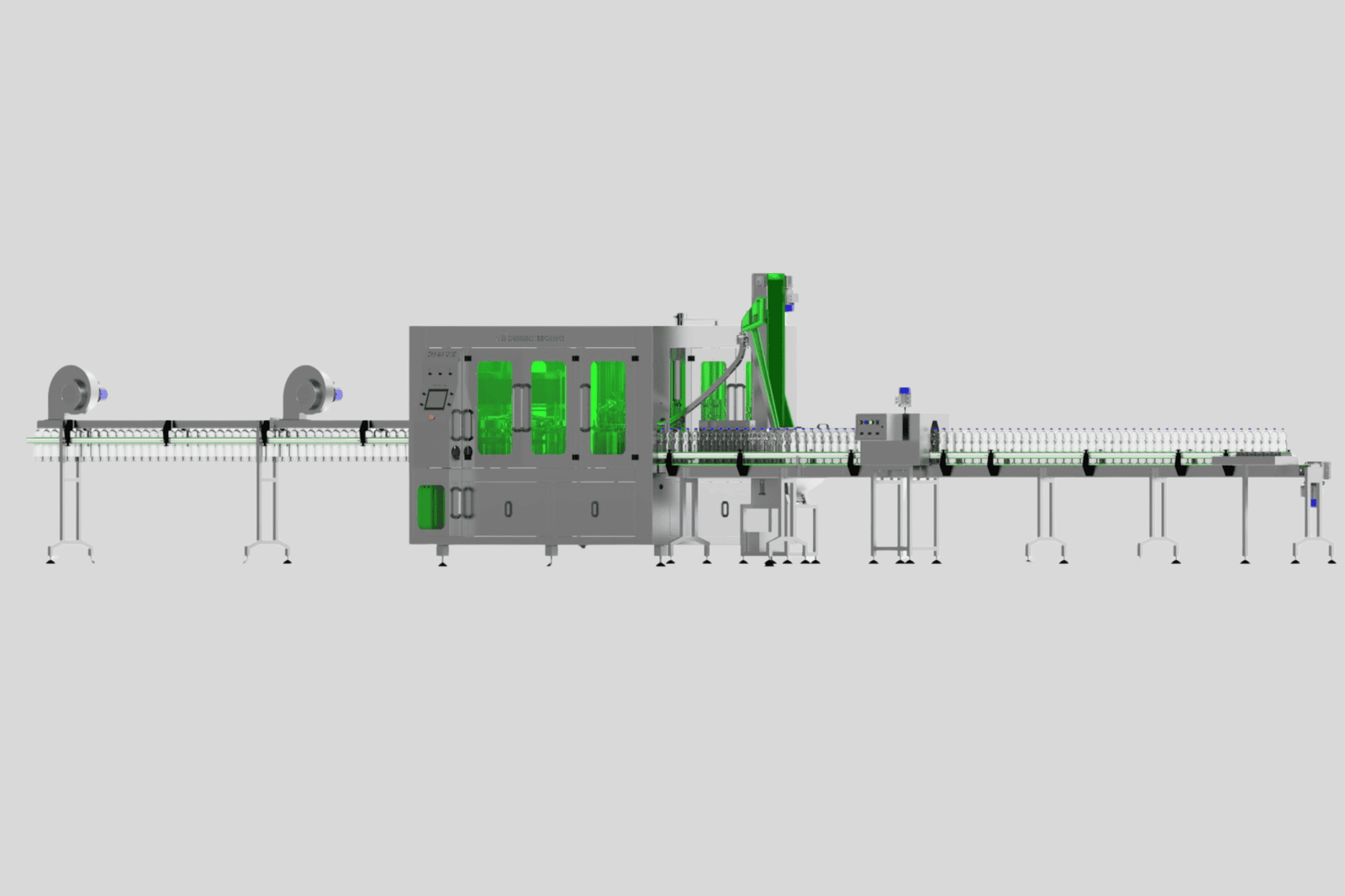

120 BPM Fully Automatic RFC Machine

The 120 BPM fully automatic RFC machine is engineered for large-scale production of carbonated beverages. Operating at 120 bottles per minute, it integrates rinsing, filling, and capping into a streamlined process. Designed with robust construction and advanced automation, this drinking water filling machine ensures minimal downtime, consistent quality, and maximum productivity. It’s the perfect choice for industries needing high-speed operations with a focus on hygiene and reliability.

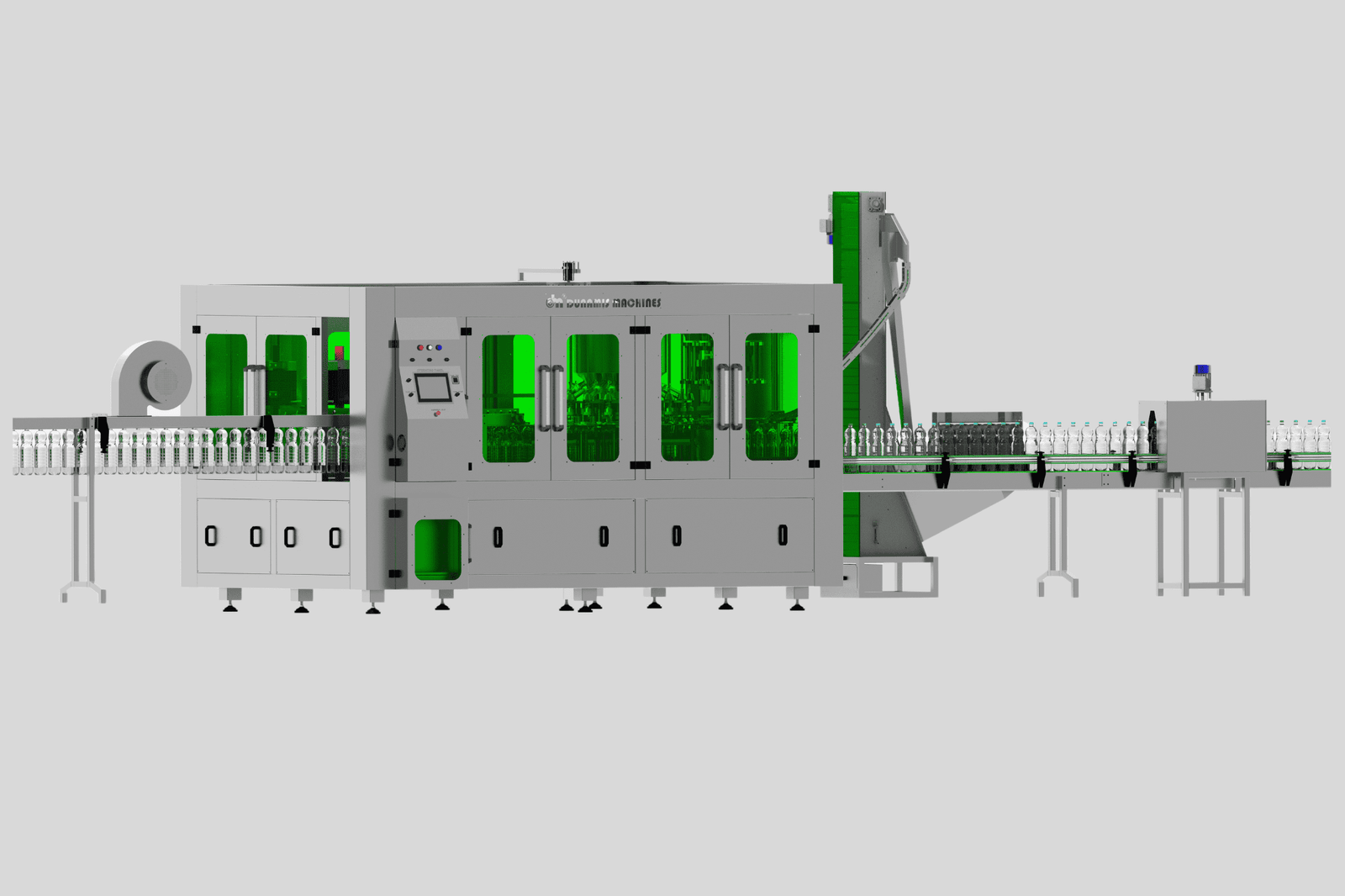

200 BPM Fully Automatic RFC Machine

The 200 BPM fully automatic RFC machine is designed for high-volume production of carbonated beverages. With a capacity of 200 bottles per minute, it seamlessly combines rinsing, filling, and capping into a single efficient process. Built with durable construction and advanced automation, this water filling machine minimizes downtime, ensures consistent output, and boosts productivity. Ideal for industries requiring fast operations, it prioritizes hygiene, reliability, and maximum efficiency in every production cycle.

Check out our full machine catalog with all the details.